Lifting KnowHow

We have the KnowHow required - we call it "The Lifting KnowHow"

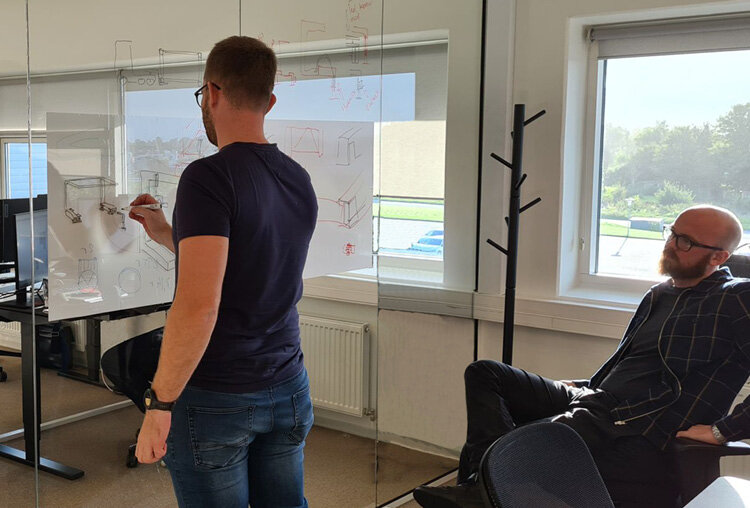

CERTEX Danmark A/S has its own innovation center in Middelfart, where our team of engineers and project managers is based. They design and construct lifting applications and lifting equipment from a few kilos capacity to large lifting beams or crane solutions capable of handling hundreds of tons. With our customized solutions, you get a product that covers exactly your needs and requirements for a specific lifting task or solution.

Our innovation center is also the place where our business development team, together with our engineers, work on ideas, design and development of our own product line which we call CTX. In order to achieve the best possible working environment for innovation and development, our team consists of both employees with many years of experience within our industry and students.

With more than 35 years of extensive experience in the development of tailored solutions and special products for both large and small lifting projects, as well as optimization initiatives both onshore and offshore, we have established ourselves as a leader in our field.

Our dedicated team of engineers and specialists bring unique expertise to each project, ensuring we can meet even the most complex requirements and challenges our clients may face.

We always strive to advise, manage, and execute our projects with a commitment to quality, safety, environmental considerations, and cost efficiency.

Below you can see and read more about some of the lifting products developed by the team in our innovation centre.

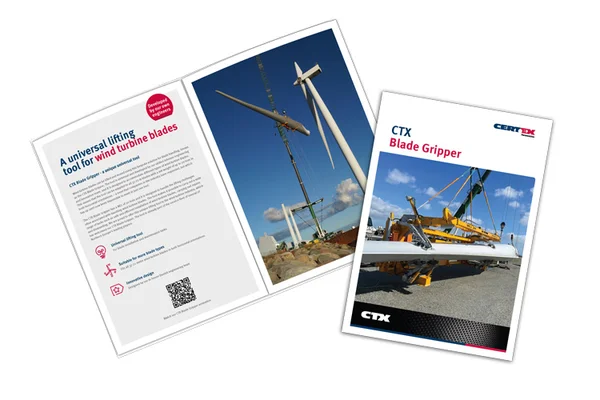

Universal lifting tool for

Universal lifting tool forThe CTX Blade Gripper can be adapted to different blade types up to a WLL of 20 tons. It is used for blade installation and -exchange, temporary storage during pitch-bearing exchange, or blade-repair jobs.

Learn more

With the CTX Tandem tool, you can add additional lifting points to a chain hoist allowing you to hoist your loads smoothly and efficiently. The tool is available for different chain sizes.

Learn more

3-legged lifting yoke with

3-legged lifting yoke withCustom-made lifting yoke designed with several special functions, e.g. a mechanical traction arm which, when activated, displaces the plates symmetrically at the outer ends of the lifting yoke.

Learn more

We are with you every step of the way - from idea to finished product.

We offer the following services:

We have the KnowHow required - we call it "The Lifting KnowHow"

We carry out break tests and load tests of many types of lifting equipment in our test bench, test tower or with Water Weights.

CERTEX Danmark A/S carries out inspection of lifting equipment, personal fall protection and cranes.