Understand the difference between steel Grades

Lifting chains and components are robust elements often used with chains, hooks, and other elements, such as connecting links. The parts are available in different steel grades, which is essential when choosing lifting chains and components.

Steel qualities approved for lifting

Regarding steel grades for lifting, terms like Grade or class are used. The most common steel grades are Grade 8, Grade 10, and Grade 12 (also referred to as Grade 80, Grade 100 and Grade 120), but other grades also exist. Components in the grades mentioned are recommended for chain slings and for lifting applications.

Why classification?

Grade is a definition of the steel alloy from which the steel item is made, and it is this that is important for which properties the component/chain has. Alloy steel consists of iron and other elements, primarily carbon. It is the amount of carbon in the iron that determines the iron's hardness and tensile strength.

We have visualized this in the animation video below, and here, you also get answers to what happens if you combine items from different grades and sizes.

Steel classifications

Grade 8 (Grade 80)

This steel alloy is the lowest grade approved for lifting applications. Chains and components in this grade are often cheaper, but larger and heavier than higher-grade items.

Grade 8 is developed for heavy lifting under demanding conditions and are suitable for use in mining, construction, and offshore rigging industries.

Grade 10 (Grade 100)

Grade 10 alloy is finer than Grade 8 and is widely used today. With components in this steel alloy, you get approximately 25% higher WLL than those in Grade 8. You can, therefore, choose a lighter chain sling (or other lifting equipment in steel Grade 10) and achieve the same or even higher WLL.

Chains and components in Grade 10 are often used in industries such as construction and mining.

Grade 12 (Grade 120)

This is the newest steel alloy for lifting on the market. It allows for higher performance and lighter chains or components. For example, with a chain sling in Grade 12, you can lift 50% more than with a chain sling in Grade 8 and 20% more than with one in Grade 10, which allows you to handle heavier loads without upgrading the crane solution. Compared to Grade 8, you can go down a size in diameter and still achieve the same WLL.

Chains and components in Grade 12 are developed for the most demanding lifting tasks requiring extreme strength and durability.

Do you have any questions?

Do you have any questions?

If you have any questions, please send us a message and we will be happy to help.

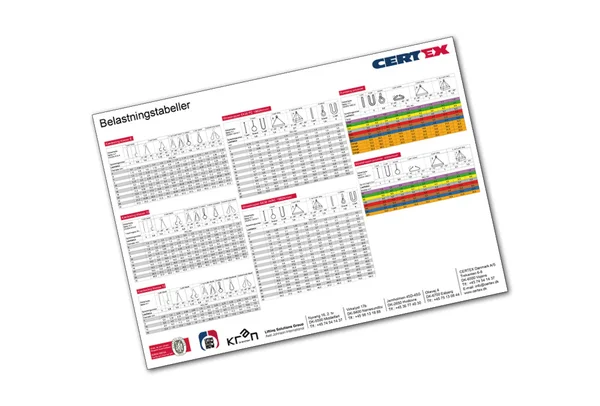

Load tables poster

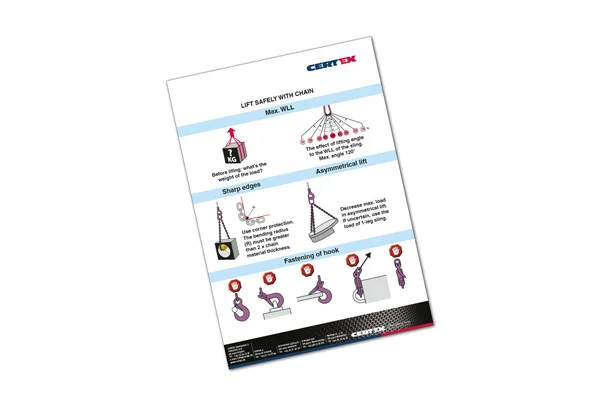

Lift safely with chain

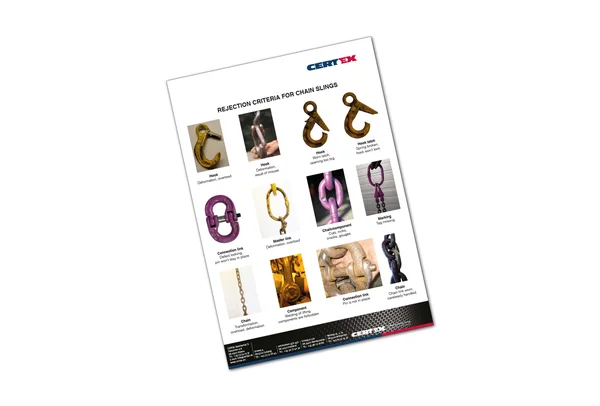

Rejection criteria for chain slings

Rejection criteria for chain slings

The benefits of Grade 10

This is why it can be an advantage to choose Grade 10 chains and components.

Good to know about chain sling

Find instructions for the safe use of chain slings.