How to choose the right lifting hook for the job

When we talk about lifting and rigging equipment, the lifting hook is often one of the most overlooked components – but also one of the most important choices. Terms like sling hook and safety hook are often used interchangeably, but there is a significant difference between the two types in design, function, and correct use. Choosing the right hook for the job directly impacts safety.

What is a sling hook?

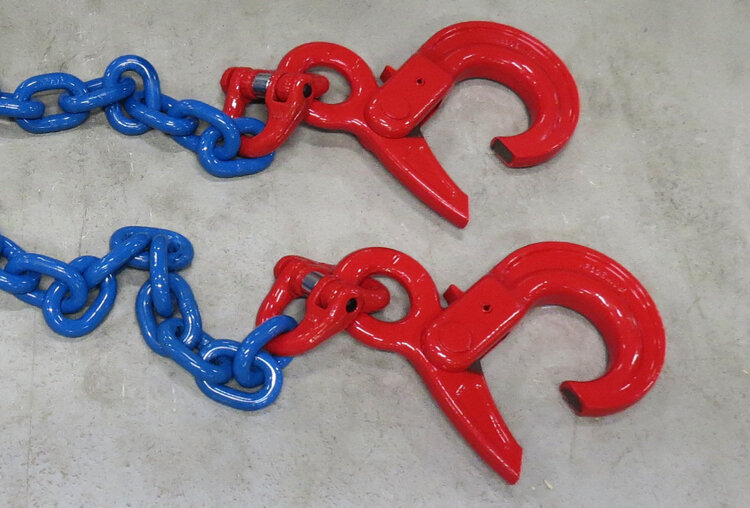

A sling hook is the classic open J-shaped hook with a relatively large hook opening. It is fitted with a spring-loaded safety latch that prevents the load from accidentally slipping off. The latch is easy to open by hand – both with and without a load in the hook.

Sling hooks are typically made from high-strength metals such as Grade 8 or 10 steel and they are often used in:

- Chain slings, wire rope slings, and webbing slings

- Securing or lifting loads

- Lifting operations where the rigger can maintain good visual control of the load throughout the entire lift

How to recognise a sling hook:

- Open hook shape with a relatively large hook opening

- Spring-loaded safety latch

- The safety latch opens inwards into the hook opening

- The latch can typically be opened easily with one hand without unloading the hook

A sling hook is often a good choice in controlled, low-risk environments where the load is stable, the rigging is simple, and the rigger has full oversight of the lift.

What is a safety hook?

A safety hook (also called a self-locking or automatic hook) has a relatively large hook opening and a robust, integrated latch that closes automatically when the hook is loaded. The hook cannot be opened while it is under load.

Safety hooks typically consist of two parts (three, if it is a swivel safety hook) and are made from high-strength metals such as Grade 8 or 10 steel. Swivel safety hooks are available with or without a bearing – a bearing model rotates more easily under load but requires ongoing maintenance and lubrication.

How to recognise a safety hook:

- Closed hook shape when the latch is engaged

- Robust, automatic locking mechanism – often operated with a handle or push button

- Closes automatically when the hook is loaded

- Requires a deliberate action to open – the hook opens outwards

- Often requires unloading of the hook or a two-step opening action

Typical applications for safety hooks:

- Lifting and transporting loads where extra safety is required

- Dynamic lifts where the load may move, swing, or “catch” suddenly

- Tasks in areas close to people or other places where a dropped load may have serious consequences

- Lifts where the rigger cannot maintain constant visual control

In many companies, safety hooks are now standard in areas where people work, precisely to minimise the risk of dropping loads.

Types of top fittings: clevis, eye, and swivel

Both sling hooks and safety hooks are typically available with either a clevis or an eye. Swivel hooks are always with an eye. The choice depends on what the hook is to be combined with – for example, in a chain sling, connecting link, or unilock. If you choose an eye hook, a connecting link/unilock must be used as the link to the rest of the equipment.

When should you choose a safety hook?

You should choose a safety hook when:

- You are lifting in areas where a dropped load may have serious consequences

- The lift is demanding – e.g., in wind, offshore, or installation work at height

- The load can move or risk slipping out of an open hook

- The customer’s or the company’s internal rules require safety hooks

When is a sling hook sufficient?

A sling hook can be the correct choice when:

- You work in controlled environments with plenty of space and low risk

- The load is stable, and the rigging is simple and clear

- The rigger has a full overview of the entire lift

- There are clear procedures and routines for correct rigging

Here, it is the combination of risk assessment, legislation/standards, and the company’s own requirements that determines the right choice.

How to tell the difference in practiceWhen you are holding the hook in your hand, you can particularly look at: 1. The locking mechanism One-hand operated safety latch that opens inwards into the hook → typically a sling hook Robust mechanical latch that closes automatically under load → typically a safety hook 2. Operation • Can the hook be opened easily with one hand without unloading? → often a sling hook? → ofte lastkrog • Does it require unloading, a special movement or a two-step opening? → often a safety hook |

It is not “either or” – but “the right tool for the job

In practice, many companies will benefit from using both types of hooks:

- Lifting hook for simple, straightforward lifts

- Safety hook for demanding, high-risk, or personnel-near areas

The most important thing is that an active decision has been made:

What is the risk associated with this lift – and has the hook been chosen accordingly? Hooks may not take up much space in the overall lifting setup – but if something goes wrong, they can be critical. So take an extra moment to choose the right hook and make sure your employees know how to tell the difference and how to use the hooks correctly.

Are you responsible for lifting and rigging?

Consider, among other things:

- Is our standard choice of hooks the right one for our tasks?

- Do employees know the difference between lifting hooks and safety hooks?

- Are our procedures and equipment up to date with current requirements?

We are happy to help you review both equipment and practice. We provide advice on choosing hooks and other lifting components – and we offer training in safe rigging, which can be tailored to your company and your tasks. Contact us if you want to be absolutely sure you have the right hook for the next job, or to book a training in safe rigging.

Do you have any questions?

Do you have any questions?

If you have any questions, please send us a message and we will be happy to help.

Training in safe rigging

Create a safe workplace. We offer courses in safe rigging and use of new lifting products.

Correct use of lifting components

In teh article "Correct use of lifting components" you will also find a video with good advice on choosing a lifting point and using it correctly.