Here is why you should take good care of your steel wires

In a time when we need to reduce the need to produce and dispose of things frequently, fortunately, there are many things you can do yourself to extend the life of the things you have bought once. Making an active effort to do this benefits the environment, safety, efficiency and, not least, the economy.

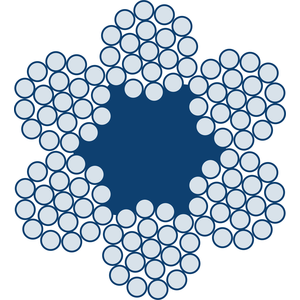

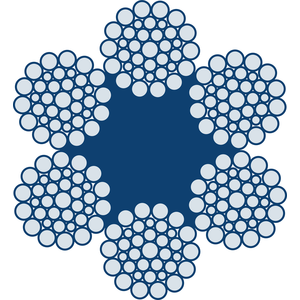

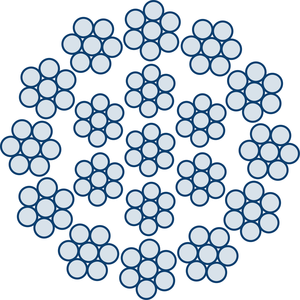

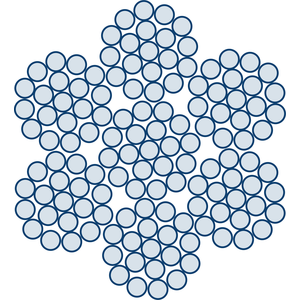

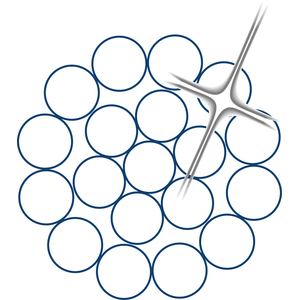

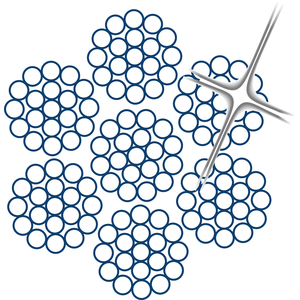

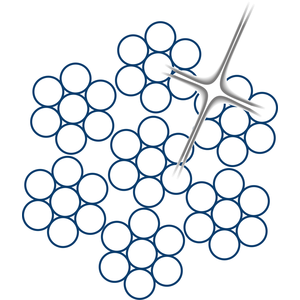

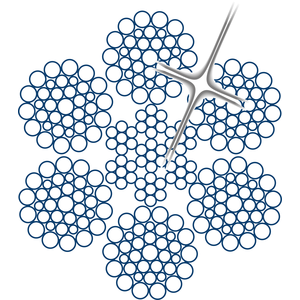

Steel wire ropes are often overlooked as a lifting and hoisting tool in terms of maintenance, but like all other lifting equipment, they also require attention and care to last a long time and provide optimal efficiency. With a few daily routines, you can do your part to keep your steel wire ropes in good condition.

To create an effective plan for extending the life of your steel wires, it is crucial to identify the threats that can cause shorter wire life.

Below we have described the most common reasons why wires last shorter than they can, and what precautions can be taken to avoid premature scrapping.

Corrosion in steel wire rope

Corrosion (or rust, as it is also known) is the most significant threat to most steel wire ropes. Rust is a natural breakdown of the steel, which occurs due to environmental factors such as oxygen, saltwater, or chemicals.

Surface rust can be removed and prevented through lubrication. In contrast, light surface rust, moderate to severe surface corrosion, and pitting corrosion weaken the metal strands in the wire, increasing the risk of damage to it.

Life-extending precautions against corrosion

When you receive a steel wire rope, it is typically lubricated with a lubricant intended to prevent corrosion of the wire during storage until it reaches the customer and is put to use.

Thereafter, regular lubrication with a suitable wire rope lubricant can help prevent or slow down the attack of rust. Surface rust is easily removed with a stiff brush or similar.

Wear damage on steel wire rope

Wear damage to steel ropes can occur in several ways. A wire rope sheave with a groove that is either too small or too large destroys both the wire and the wire rope sheave. Rubbing against sheaves or through drums can also cause unwanted wear of the wire. Dirt, grit and poor lubrication also accelerate the wear of the wire.

Life-extending precautions against wear

Always ensure the wire rope is kept free from dirt, such as grit, sand, and corrosion. Regularly check that the wire sheaves and wire grooves are not worn or have sharp edges, and ensure that the wire runs correctly in the wire grooves in the wire sheave and drum

Bending fatigue in steel wire rope

Bending fatigue occurs when a wire is subjected to frequent bending during constant use, particularly when the bending radius is small. This usually leads to wire breakage, which gradually weakens the steel wire rope. Bending fatigue mostly occurs in the final stages of the steel wire rope's service life.

Life-extending precautions against bending fatigue

If external wire breakage due to bending fatigue occurs, a competent person can correct it by fastening the broken wire; however, it is better to prevent it from happening in the first place. This can be prevented by ensuring an appropriate bending radius in the lifting system.

Do not expose the wire rope to kinking. There is a particular risk of kinking when handling or unwinding the wire after delivery. In the article Installation of steel wire rope you can find more information about this and watch a short animation video on the correct handling of steel wire rope.

Wire rope fleet angle

By allowing the wire rope to work with a too large wire rope fleet angle, it can cause severe wear of the wire rope against the nearby wire layers on the drum. It can also cause twisting problems, where the wire rope rotates around its own axis.

This adds a twist into or out of the steel wire rope, which in the worst case can result in a protruding wire core or the formation of a “bird’s nest”.

Life-extending precautions against damage due to incorrect wire rope fleet angle

To avoid damage to the wire rope due to incorrect wire rope fleet angle, you can reduce the wire rope fleet angle by either reducing the drum width or increasing the drum diameter. Another method can be to increase the distance between the wire rope sheave and the wire rope drum.

Storage of the steel wire rope

When the steel wire rope is not to be used immediately but is to be stored for a shorter or longer period, it is essential to store the steel wire rope correctly. Incorrect storage can cause the wire rope to become contaminated with unwanted objects, and it may begin to rust before it is taken into use

Precautions to extend the life of the wire rope

If the wire rope has been delivered on a drum and is to be stored for an extended period, the drum must be rotated at regular intervals. This prevents the lubricant supplied with the wire rope from seeping out.

If the wire rope is to be stored outdoors, it must be covered with a waterproof material to prevent exposure to rain or snow. If the wire rope is to be stored indoors, it must be in a clean, well-ventilated, dry and dust-free area. Avoid exposure to chemical fumes, smoke or other corrosive substances.

Regular inspections of steel wire rope

As with all lifting equipment, it is recommended to carry out regular visual inspections of the steel wire rope (preferably daily, or before each use), and, of course, comply with the statutory annual inspections. If you have any doubts about the condition of the equipment, please don't hesitate to contact a specialist.

We have trained service technicians who can help with such inspections. Please get in touch with us to arrange an appointment.

It can also be a solution to have a Rope Watcher™ installed on the ropes that are difficult to access or are in constant use. With it, you always get data on the rope's condition displayed in real-time on your phone or other device, and can take immediate action.

Do you have any questions?

Do you have any questions?

If you have any questions, please send us a message and we will be happy to help.

ROPETEX wire lubricants

Steel wire rope use and maintenance

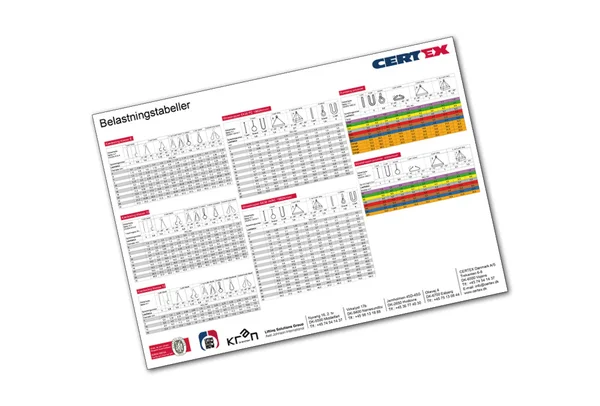

Load tables poster

Discard of steel wire rope

Steel wire wears out during use and must, therefore, be inspected regularly. Find out more about inspection and discard criteria for steel wire rope.

Installation of steel wire rope

Learn how to unwind your new steel wire rope from the packaging, and how to "run in" the rope correctly before use.

Corrosion or rust on steel wire rope

There are several levels of corrosion on steel wires. Please take a look here at which ones and what they mean for the continued use of the wire.