How do I choose the correct steel wire rope?

We have collected 10 questions in the below table that can help you find out which steel wire rope is best suited to your specific needs.

A correctly selected steel wire rope means as long a service life as possible, provided that the wire is maintained with inspection and correct lubrication.

Choosing your steel wire rope

When ordering your new steel wire rope, ensure about the right type, construction, dimension and length. Follow the machine manufacturers recommendations and assure that the equipemnt has the right machine group/grade.

WARNING! Wrong choice of steel wire rope can cause reduced working life, fracture of rope and/or damage of equipment.

The following questions can help you to choose the right construction of steel wire rope. If you have conflicting answers, you shall choose the most frequent alternative. Putting together the ten aswers will help to choose the most optimum wire rope construction, but other questions and/or considerations can sometimes lead to another wire rope construction.

For further advice, please contact CERTEX Danmark A/S.

| Question | Yes | Yes and noj | No | |

|---|---|---|---|---|

| 1 | "Rotation resistance" demanded? | "Rotation resistant" wire rope | "Rotation resistant" wire rope | 6/8/9/10-strand wire rope |

| 2 | High breaking load demanded? | Special wire rope, compacted | Wire rope with steel core | - |

| 3 | Lots of bendings? | Multistrand wire rope with small outer wires | Multistrand wire rope with small outer wires | - |

| 4 | Large outer wear? | Wire rope with large outer wires | Wire rope with large outer wires | - |

| 5 | Coiled in many layers? | Langs lay wire rope, compacted | - | Ordinary hand lay rope |

| 6 | Risc of deformation/damage? | Wire rope with plastic encapsulated core | Wire rope with plastic encapsulated core | - |

| 7 | Large rope guide angle? | Wire rope with plastic encapsulated core | Wire rope with plastic encapsulated core | - |

| 8 | Left groove drum? | Right hand lay | - | Left hand lay |

| 9 | Left drawn rope guide? | Right hand lay | - | Left hand lay |

| 10 | Corrosive environment? | Galvanized/stainless wire rope | Galvanized/stainless wire rope | Bright/galvanized wire rope |

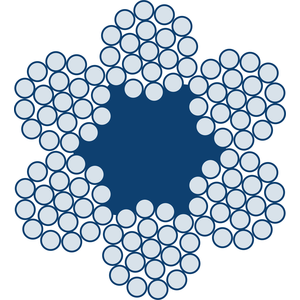

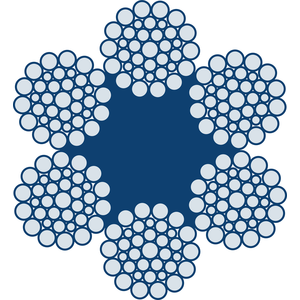

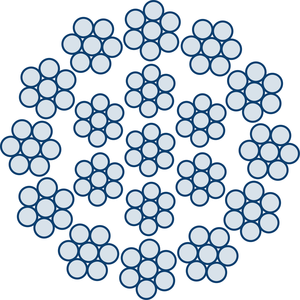

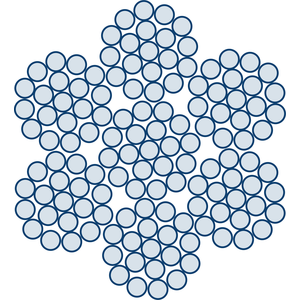

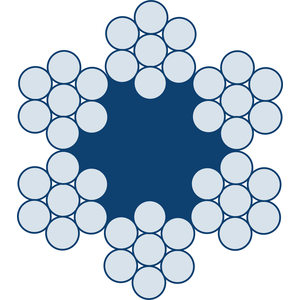

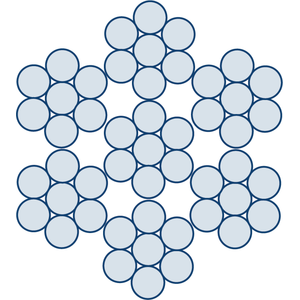

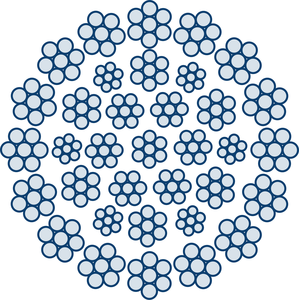

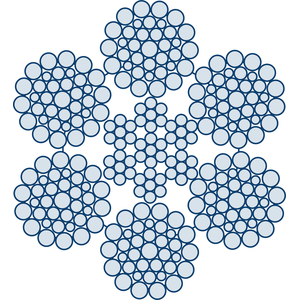

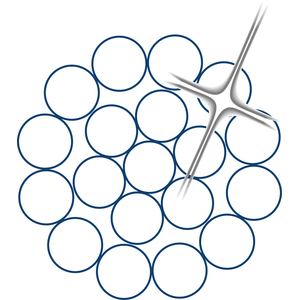

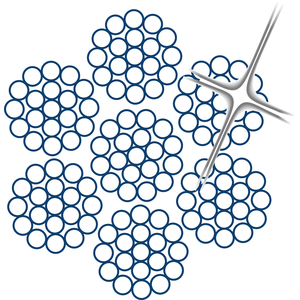

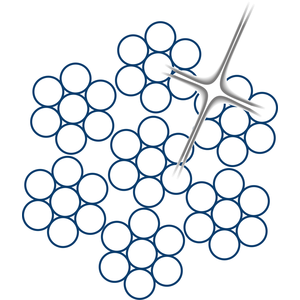

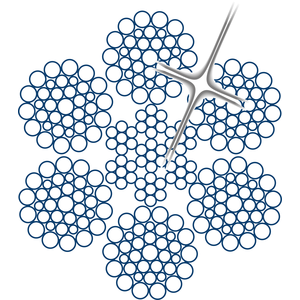

Rotation resistance

To minimise the tendency to rotate especially with high lifting heights "rotation resistant" or "Low Rotation" ropes should be used.

Rotation resistant ropes are made out of many layers of strands. Every layer is laid in the opposite direction to the next layer, so that the torque in the different layers balances the opposing forces in the rope.

Definitions of breaking load

Minimum breaking load (MBL)

The minimum breaking force (minimum breaking load), in kilonewtons, is the lowest breaking strain of the rope when tested to destruction.

Calculated breaking load

The value calculated from the product of the sum of the crossectional metallic areas of all the individual wires in the rope and the tensile strength grade(s) of the wires. The total metallic area is directly proportional to the square of the nominal diameter of the rope. A standard spinning loss factor that results from the twisting of strands and wire is then applied.

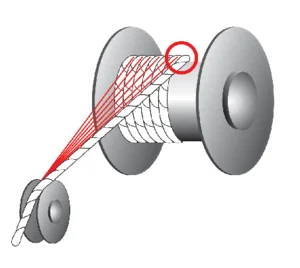

Fleet angle

Too large a fleet angle can cause excessive wear of the rope against the adjacent flange on the drum. This can also lead to torsional problems.

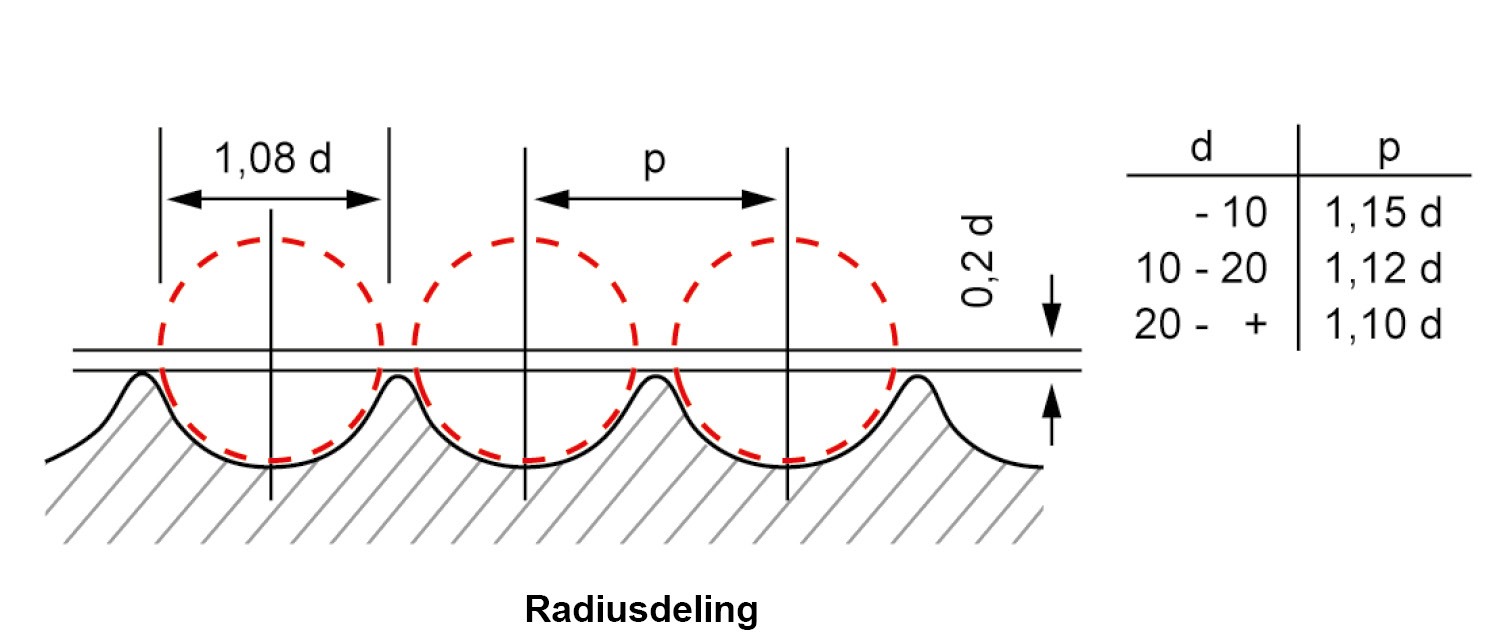

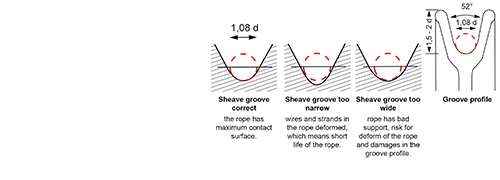

Wire rope grooves

Wire rope grooves should support the rope along approx. 1/3 of its circumference. CERTEX Danmark recommends a groove diameter of 1,08 x d, where d = nominal wire rope diameter.

Sheaves

Before installing a new rope the sheave grooves, layers and lubrication should be checked.

Measure the groove diameter with a radius gauge and check the general condition of the groove.

Groove diameter shall be nominal rope diameter +8% to +14% (0,54 x d to 0,57 x d).

Warning! Worn sheaves should be replaced/refurbished.

Maintenance - lubrication

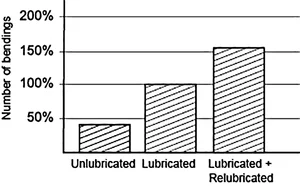

When a steel wire rope is in operation wires are weared against each other. To reduce the friction the wire rope is lubricated by manufacturing (see Webinar Basics about steel wire rope). The lubrication improves the function of the steel wire rope and increases its service life.

Check the lubrication of the rope immediately after installation and clean the rope from impropriate material, e.g. sand and dirt, eventually the wire rope also has to be completed with lubrication before use.

It is also important that lubrication is made in intervals of even time depending on valid operation conditions.

WARNING! An unlubricated or incorrect lubricated wire rope has considerable shortened life.

WARNING! An unlubricated or incorrect lubricated wire rope has considerable shortened life.

For more information about wire rope lubrication, read our article "How to keep your wire rope in good condition", or contact CERTEX Danmark for further advise and help about lubrication.

Do you have any questions?

Do you have any questions?

If you have any questions, please send us a message and we will be happy to help.

ROPETEX lubricants

Steel wire rope use and maintenance

Load tables poster

Technical description steel wire rope

Learn about length tolerances, dimensioning and a lot more

Installation of steel wire rope

Learn how to unwind your new steel wire rope from the packaging, and how to "run in" the rope correctly before use.

When should my steel wire rope be discarded?

Steel wire ropes wear out during use and must therefore, be inspected regularly. Learn more about inspection and discard criteria for steel wire ropes.