Hazardous conditions

Particularly hazardous conditions including offshore activities, the lifting of persons and lifting of potentially dangerous loads such as molten metals, corrosive materials or fissile materials. In such cases the degree of hazard should be assessed by a competent person and the working load limit adjusted accordingly.

Wire rope slings

General: Steel wire rope slings are in most cases easier and less expensive than chain slings. Galvanised wire rope provides good protection against corrosion, in extreme environments stainless wire ropes can be used. For extremely heavy lifting wire rope slings are usually the best option.

Material/Design: For manufacturing of wire rope slings the rope grade shall be either 1770 or 1960 N/mm². In multi-leg slings the rope dimension and grade shall be the same for each leg. The working load limit of the lower terminal fitting(s) shall be at least equal to that of the leg(s) to which it is/they are fitted. Where a terminal fitting is used, the eye termination shall always be fitted with a thimble. For 3- and 4-leg slings a master link with intermediate link should bee used.

Safety factor: 5:1

Standard: EN 13414-1

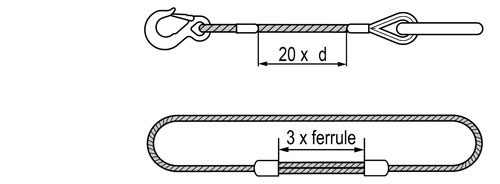

Ferrule/Splicing

The minimum length of plain rope between the inside ends of ferrules terminating a sling leg shall be 20 times the nominal rope diameter. The minimum length of plain rope between the tails of splices shall be at least 15 times the nominal rope diameter. For endless sling the length between the ferrules shall not be less than three times the length of the ferrule after pressing

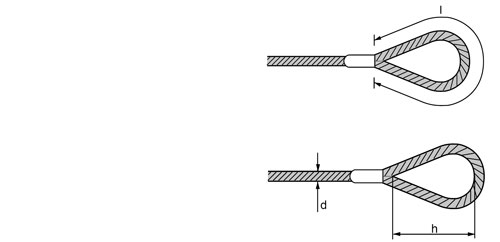

Soft eye

The peripheral length (l) of a soft eye shall be at least four rope lay lengths. CERTEX apply as standard that the length (h) of the soft eye shall be at least 15 times the rope diameter (d).

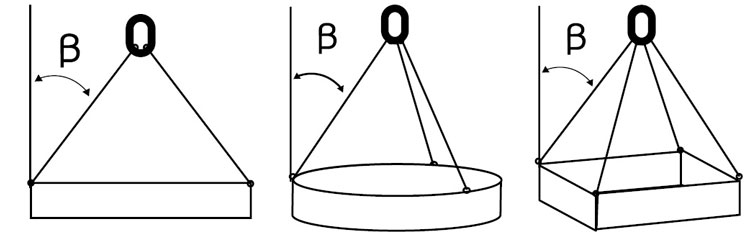

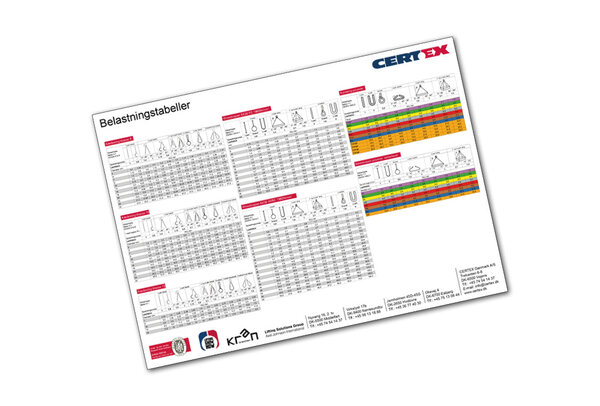

Multi-leg slings

The working load limit of any master link shall be at least equal to that of the sling. The working load limit of any intermediate link fitted to a three-leg or four-leg sling shall be at least equal to 1,6 times the WLL of one of the legs suspended from it.

WARNING! When using the steel wire rope sling for projected lifting with an angel (ß) less then 45°, the working load limit will increase. This shall be informed by the time of order.

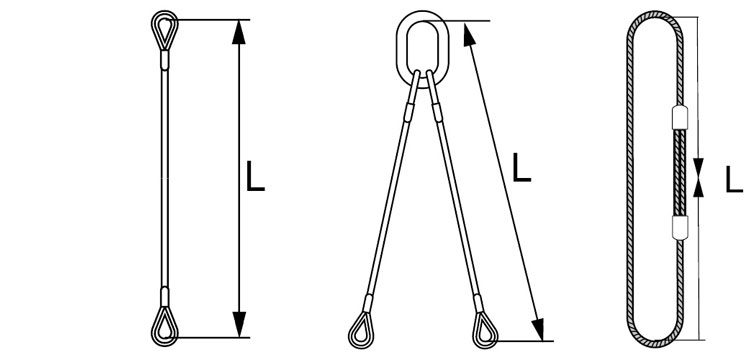

Length

Length: The length (L) shall be that measured between the bearing points of the sling or the circumference length of an endless sling.

Single leg and endless slings: The measured length of a ferrule-secured sling shall not differ from the nominal length by more than two rope diameters or 1% of the nominal length, whichever is the greater.

The measured length of a spliced sling shall not differ from the nominal length by more than four rope diameters or 2% of the nominal length, whichever is the greater.

Where single leg slings are intended to be used as matched sets, the difference in length of matched sets of ferrule-secured eye slings shall not exceed the rope diameter, or 0,5% of the nominal length, whichever is the greater.

Multi leg slings: The measured individual leg length of a ferrule-secured sling shall not differ from the nominal length of the sling by more than two rope diameters or 1% of the nominal length, whichever is the greater.

The difference in length between the individual legs of any multi-leg sling under no load shall not exceed 1,5 times the rope diameter or 0,5% of the nominal length, whichever is the greater.

"Laid" (cable-laid) endless slings: The measured length for cable-laid grommets with diameter <61 mm the tolerance shall be ±1d or 1% of the nominal length, whichever is the greater. For cable-laid grommets with diameter >65 mm the tolerance shall be ±0,5d or 0,5% of the nominal length, whichever is the greater.

Marking

Each sling shall be provided with a marking plate or be marked in the ferrules (single leg and endless slings) with the manufacturer's identifying mark, working load limit (WLL), length, manufacturing date and CE marking.

Wire rope fittings

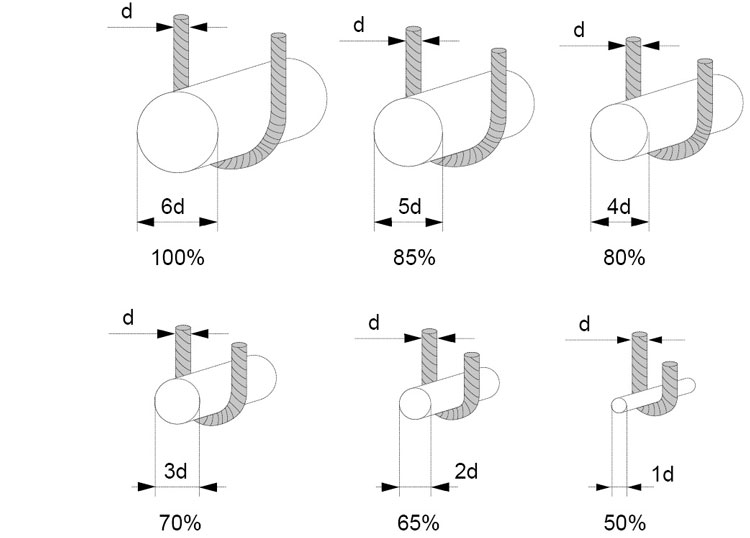

The most commonly used rope fittings with indication of remaining percentage of steel wire min breaking force.

Dimensioning for steel wire rope slings

Working load limit (WLL) for steel wire rope sling

Single leg sling

WLL (ton) = (Fmin x KT) / (Zp x g)

Endless sling (choke)

WLL (ton) = (Fmin x KT x 2 x 0,8) / (Zp x g)

Multi-leg sling

WLL (ton) = (Fmin x KT x KL) / (Zp x g)

Fmin = the minimum breaking force of the rope, in kN.

KT = factor for the efficiency of the termination, for ferrule 0,9 and for spliced 0,8.

KL = the leg factor relating to the number of legs and the angle to the vertical, see WLL-table. Zp = the coefficient of utilization (working coefficient), with the value 5. g = 9,81

Bending diameters effect on the working load limit (WLL)

CERTEX recommend that consideration will be taken to that the slings capacity will be lower when the bending diameter decreasing. If, for example the rope bends around a bearing point witch have the same diameter as the rope itself the capacity will decrease to the half, see figure.

Working Load Limit (WLL)

Wire rope sling 6X36 FC - 1960 N/mm²

When using a multi-leg sling in a choker hitch - reduce the value with 20%

| Single | 2-leg sling* | 3- and 4-leg sling* | Endless | |||||||

|

|

|

|

|

|

|

|

|||

| Angle of inclination | 1-leg | Laced | U-lift | 0°- 45° | 45° - 60° | 0°- 45° | 45° - 60° | 1-part | Laced | U-lift |

| Loadfactor | 1 | 0,8 | 2 | 1,4 | 1 | 2,1 | 1,5 | 2 | 1,6 | 4 |

| mm | WLL ton | |||||||||

| 8 | 0,75 | 0,6 | 1,5 | 1,1 | 0,75 | 1,6 | 1,1 | 1,4 | 1,2 | 3 |

| 9 | 0,9 | 0,8 | 1,8 | 1,26 | 0,9 | 2 | 1,4 | 1,8 | 1,5 | 3,6 |

| 10 | 1,2 | 0,95 | 2,4 | 1,7 | 1,2 | 2,5 | 1,8 | 2,4 | 1,9 | 4,8 |

| 11 | 1,4 | 1,1 | 2,8 | 2 | 1,4 | 3 | 2,2 | 2,8 | 2,3 | 5,6 |

| 12 | 1,7 | 1,3 | 3,4 | 2,4 | 1,7 | 3,6 | 2,6 | 3,4 | 2,7 | 6,8 |

| 13 | 2 | 1,6 | 4 | 2,8 | 2 | 4,2 | 3 | 4 | 3,2 | 8 |

| 14 | 2,3 | 1,8 | 4,6 | 3,2 | 2,3 | 4,8 | 3,5 | 4,6 | 3,7 | 9,2 |

| 16 | 3 | 2,4 | 6 | 4,2 | 3 | 6,3 | 4,5 | 6 | 4,8 | 12 |

| 18 | 3,8 | 3,1 | 7,6 | 5,3 | 3,8 | 8 | 5,7 | 7,6 | 6,1 | 15,2 |

| 20 | 4,7 | 3,8 | 9,4 | 6,6 | 4,7 | 10 | 7,1 | 9,4 | 7,6 | 18,8 |

| 22 | 5,7 | 4,6 | 11,4 | 8 | 5,7 | 12 | 8,5 | 11,4 | 9,2 | 23 |

| 24 | 6,8 | 5,4 | 13,6 | 9,5 | 6,8 | 14,3 | 10,2 | 13,6 | 11 | 27 |

| 26 | 8 | 6,4 | 16 | 11,2 | 8 | 16,8 | 12 | 16 | 12,8 | 32 |

| 28 | 9,3 | 7,4 | 18,6 | 13 | 9,3 | 19,5 | 14 | 18,6 | 15 | 37 |

| 32 | 12 | 9,7 | 24 | 16,8 | 12 | 25,5 | 18 | 24 | 19,5 | 48 |

| 36 | 15 | 12 | 30 | 21 | 15 | 32 | 23 | 30 | 25 | |

Wire rope sling 6X36 IWRC - 1960 N/mm²

| Single | 2-leg sling | 3- and 4-leg sling | Endless | |||||||

|

|

|

|

|

|

|

|

|||

| Angle of inclination | 1-leg | Laced | U-lift | 0°- 45° | 45° - 60° | 0°- 45° | 45° - 60° | 1-leg | Laced | U-lift |

| Load factor | 1 | 0,8 | 2 | 1,4 | 1 | 2,1 | 1,5 | 2 | 1,6 | 4 |

| mm | WLL ton | |||||||||

| 8 | 0,8 | 0,65 | 1,6 | 1,15 | 0,8 | 1,7 | 1,2 | 1,6 | 1,3 | 3,2 |

| 9 | 1,05 | 0,8 | 2,1 | 1,45 | 1,05 | 2,2 | 1,8 | 2,1 | 1,7 | 4,2 |

| 10 | 1,3 | 1 | 2,6 | 1,8 | 1,3 | 2,7 | 1,9 | 2,6 | 2 | 5,2 |

| 11 | 1,5 | 1,2 | 3 | 2,2 | 1,5 | 3,3 | 2,3 | 3 | 2,5 | 6 |

| 12 | 1,8 | 1,4 | 3,6 | 2,6 | 1,8 | 3,9 | 2,8 | 3,6 | 3 | 7,2 |

| 13 | 2,2 | 1,8 | 4,4 | 3 | 2,2 | 4,5 | 3,2 | 4,4 | 3,5 | 8,8 |

| 14 | 2,5 | 2 | 5 | 3,5 | 2,5 | 5,3 | 3,8 | 5 | 4 | 10 |

| 16 | 3,3 | 2,6 | 6,6 | 4,6 | 3,3 | 6,9 | 4,9 | 6,6 | 5,2 | 13,2 |

| 18 | 4,1 | 3,3 | 8,2 | 5,8 | 4,1 | 8,7 | 6,2 | 8,2 | 6,6 | 16,4 |

| 20 | 5,1 | 4,1 | 10,2 | 7,2 | 5,1 | 10,7 | 7,7 | 10,2 | 8,2 | 20,4 |

| 22 | 6,2 | 5 | 12,4 | 8,7 | 6,2 | 13 | 9,3 | 12,4 | 10 | 24,8 |

| 24 | 7,4 | 5,9 | 14,8 | 10,3 | 7,4 | 15,5 | 11,1 | 14,8 | 11,8 | 29,6 |

| 26 | 8,7 | 7 | 17,4 | 12,1 | 8,7 | 18,2 | 13 | 17,4 | 13,8 | 34,8 |

| 28 | 10 | 8 | 20 | 14 | 10 | 21 | 15 | 20 | 16 | 40 |

| 32 | 13 | 10,4 | 26 | 18,4 | 13 | 27,5 | 19,7 | 26 | ||

Do you have any questions?

Do you have any questions?

If you have any questions, please send us a message and we will be happy to help.

ROPETEX lubricants

Steel wire rope use and maintenance

Load tables poster

Steel Wire Rope ROPETEX S14

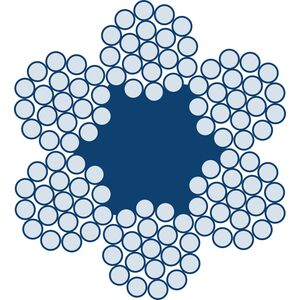

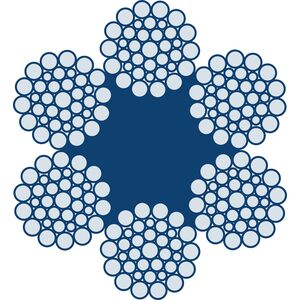

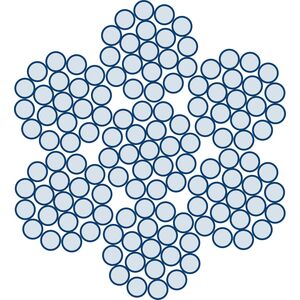

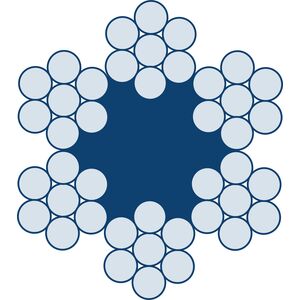

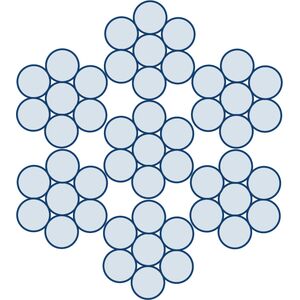

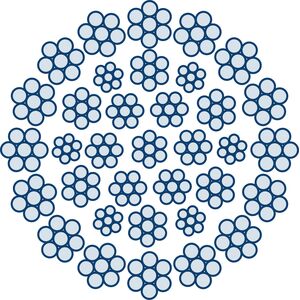

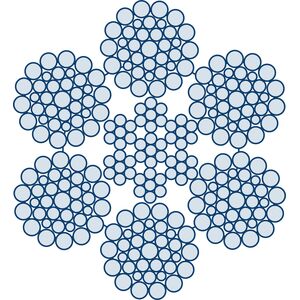

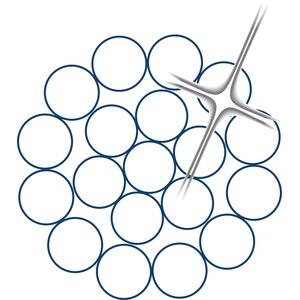

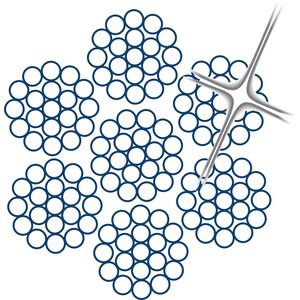

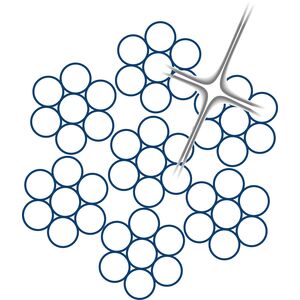

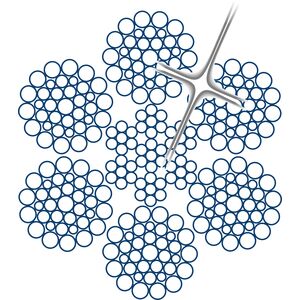

- Rope construction: 6x19M-FC

Steel Wire Rope ROPETEX S16

- Rope construction: 6x36WS-FC

Steel Wire Rope ROPETEX S18

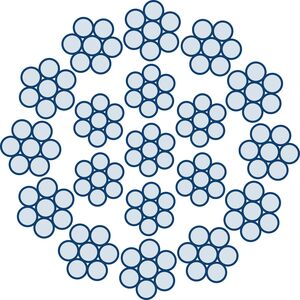

- Rope construction: 18x7-WSC

Steel Wire Rope ROPETEX S33

- Rope construction: 6x19M-WSC

Steel Wire Rope ROPETEX S42

- Rope construction: 6x7-FC

Steel Wire Rope ROPETEX S49

- Rope construction: 6x7-WSC (7x7)

Steel Wire Rope ROPETEX S55

- Rope construction: 35(W)x7

Steel Wire Rope ROPETEX S65

- Rope construction: 6x36WS-IWRC

Steel Wire Rope ROPETEX S19 Stainless Steel

- Rope construction: 1x19

Steel Wire Rope ROPETEX S33 Stainless Steel

- Rope construction: 6x19M-WSC

Steel Wire Rope ROPETEX S49 Stainless Steel

- Rope construction: 6x7-WSC (7x7)

Steel Wire Rope ROPETEX S65 Stainless Steel

- Rope construction: 6x36WS+IWRC

Lubricant ROPETEX ultra lube 2

- Color/texture: Matte black grease

Lubricant ROPETEX traction lube 40

- Color/texture: White water fluid.

Lubricant ROPETEX heavy duty lube 70

- Color/texture: Glossy black gel.

Lubricant ROPETEX thin lube 30

- Color/texture: Brown opaque fluid.

Technical description of steel wire rope

Learn more about steel wire rope, what does a rope consist of, wire, strand, lay and core.

How do I choose the correct steel wire rope?

What to consider when choosing your wire rope

Installation of steel wire rope

Learn how to unwind your new steel wire rope from the packaging, and how to "run in" the rope correctly before use.